Athena Engineering Services has worked with some outstanding companies on the cutting edge of technology in the oil & gas and other industries. Below, we've provided some case study examples of our work to demonstrate our partnering capabilities with customers. In addition to control systems and custom modeling software for dynamic forces, tubing fatigue, well intervention, extended reach, and hydraulics, we can create web and mobile applications to your specification and tailored to your business process or well intervention procedures.

If you have any questions about the studies or how we can help you achieve your goals, contact us to discuss.

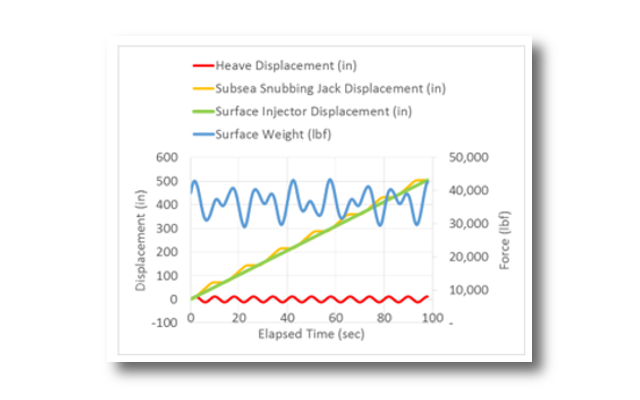

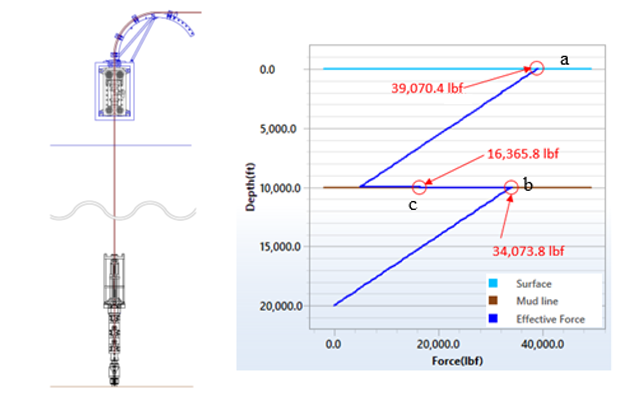

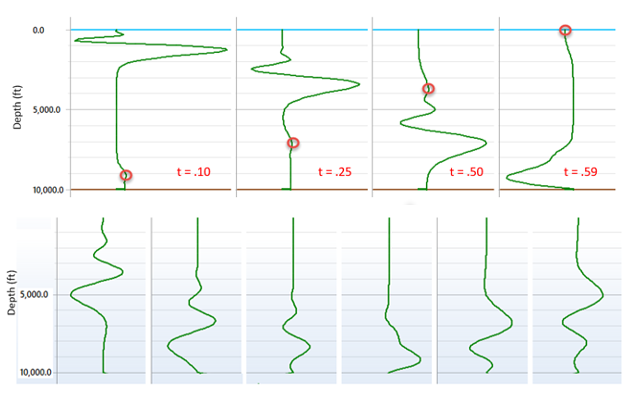

- High stress to yield ratios in heavy seas

- Catastrophic buckling in the water column

- Synchronization of tubing payout and wellhead entry rates

- Subsea wellhead snubbing at high differential pressures

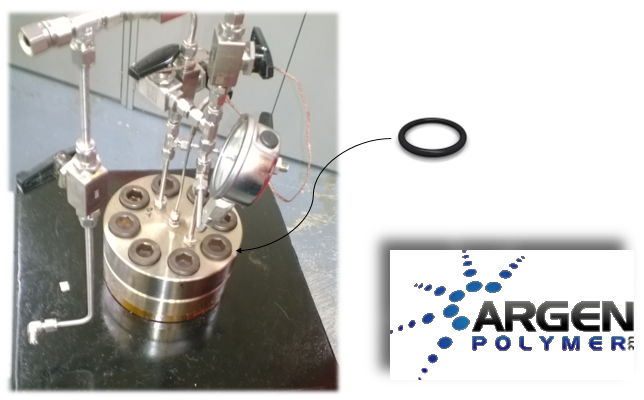

Life time estimation testing (LET) of elastomeric seals is a key component to engineering safe and economical completions and wellhead assemblies. This practice, specified by API 17D, Annex J.4.1 provides accelerated aging data by exposing a functional pressure seal to various chemical compositions and pressures expected downhole at a schedule of greatly increased temperatures until seal failure in a laboratory setting. These tests have traditionally been performed manually by highly skilled technicians with corresponding high labor costs. Argen presented us with the challenge to develop an automated test system to augment the process with a programmatic stage gate control and data acquisition system while reducing the overall operating cost and skilled labor required to perform these testing regimes.

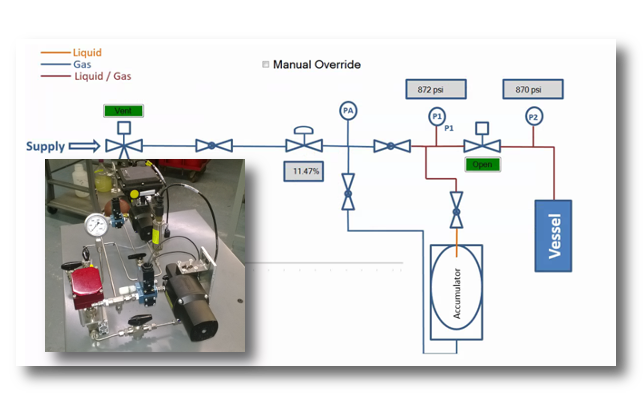

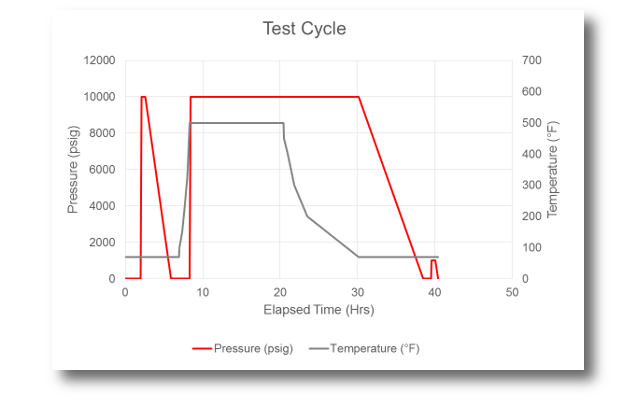

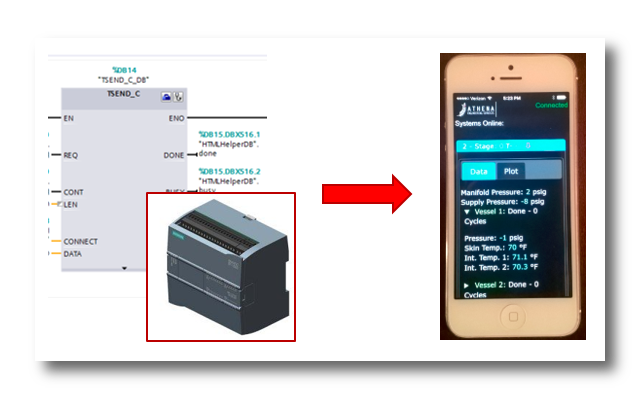

Development of the LET automation system required design and integration of thermal and pressure control systems with a focus on maintainability and economy. This was achieved using a Siemens PLC as the primary controller managing a preexisting heater control system as well as new analog and digital components. Features such as PID control with varying PID coefficient tables, RS-485 Modbus communications, TCP/IP over Ethernet, digital and analog IO were leveraged to create broad system functionality including: pressure and temperature control based on user defined stage tables, seal failure determination, linear decompression ramps with feedback compensation for the Joule-Thomson effect, calibration for thermal transfer factors, continuous data logging to multiple PCs, and plant status web pages for remote monitoring.

"The iOS application is outstanding! Thank you for your attention to detail in the design and development of this system."